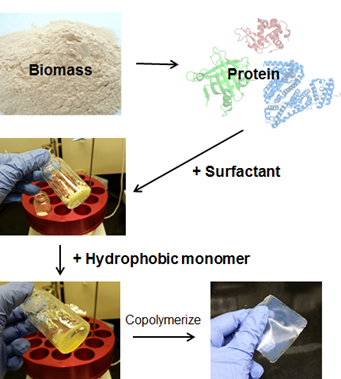

Polyurethanes are one of the most widely utilized polymeric materials in modern society, serving as construction materials, thermoplastic rubbers, and coatings, just to name a few major applications. However, the isocyanates used to make polyurethanes are extremely toxic and dangerous to handle and produce, and polyurethanes are not sustainably sourced. Due to the similarity between peptide bonds and urethane bonds in terms of their propensity for hydrogen bonding and crystallization, the Olsen lab has engineered proteins and polypeptides into resins which can lead to a new generation of sustainable and environmentally compatible alternatives to synthetic polyurethanes. We developed novel protein-based materials and solutions to produce value-added products from diverse protein sources.

Examples of applications include protein-based, non-isocyanate packaging materials with antioxidant properties. We are continually exploring new strategies to incorporate proteins into materials through different protein modifications, polymerization chemistries, and processing methods. A combination of techniques, including spectroscopy, microscopy, scattering, mechanical testing, and rheology, are being used to investigate the structure-property relationships in these materials.

Highlighted Publications

1. Chan, W. Y., Bochenski, T., Schmidt, J. E., & Olsen, B. D. (2017). Peptide domains as reinforcement in protein-based elastomers. ACS Sustainable Chemistry & Engineering, 5(10), 8568-8578. Link

2. Chan, W. Y., King, E. J., & Olsen, B. D. (2019). Hydrophobic and Bulk Polymerizable Protein-Based Elastomers Compatibilized with Surfactants. ACS Sustainable Chemistry & Engineering, 7(10), 9103-9111. Link